Supplier Details

Add to My Basket

You can manage your basket in member center

Add to My Basket

You can manage your basket in member center

Overview

deep groove ball bearings mainly support radial load as well as moderate axial load. with less coefficient of friction, high limit speed, and large size range and various structure.

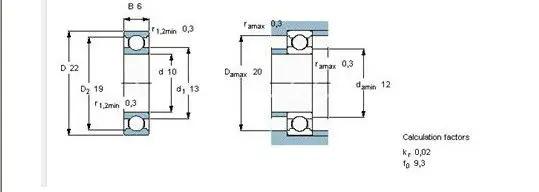

production structure:

Application Area:

this kind of bearings are suitable for precise instruments, low nosie motor, automobile, motorcycles and other common machinery, which is widely used in machinery industry.

Advantage:

Deep groove ball bearing has the advantages of simple structure, and other types are easy to achieve high manufacturing accuracy, so easily into a series of mass production, the manufacturing cost is low, use is very common. Deep groove ball bearing except basic types, there are a variety of variant structure, such as: with deep groove ball bearings, rubber sealed deep groove ball bearings, with a stop row deep groove ball bearings, ball filling gap is big load capacity of deep groove ball bearing, deep groove ball bearings.

Usage

1. Correct installation, for it affects bearings' precision, life, performance.

2. Don't use hammer striking the bearing and transfer roller pressure.

3. Use the appropriate installation tool .

4. Lubricate the bearing with high quality mineral oil to avoid rust.

5. Checking the bearings regularly, such as the surrounding temperature, vibrate, noise inspection

6. Keep bearing cleaning from dirt, dust, pollutant, moisture.

7. Bearings should not be ultra cooled